| By Linyi Zheng |

China’s largest chipmaker, Semiconductor Manufacturing International (SMIC), has recently set up a new semiconductor production line in Shanghai. The production line aims to mass-produce chips designed by tech giant Huawei, despite several years of U.S. sanctions imposed to curb China’s technological advances. SMIC’s move supports Beijing’s goal of achieving chip self-sufficiency and is seen as a secret weapon to break the blockade.

Smaller Processors, Bigger Advances

SMIC is set to deliver advanced seven-nanometer processors to Huawei in 2024. This has caused quite a stir within China. SMIC’s next goal is to use its current inventory of U.S.- and Dutch-made equipment to produce an even tinier, more advanced line of 5-nanometer chips. These chips will be used to create Kirin chips designed by Huawei’s HiSilicon for new versions of their high-end smartphones, as reported by the Financial Times.

According to The Financial Times, China’s semiconductor industry is gradually making progress despite U.S. export controls. They have recently developed a new production line that can produce 5-nanometer chips. Although these chips are still a generation behind the world’s most advanced 3-nanometer chips, if they are successfully used in smartphones, Huawei’s Rise 920 chip, which is the company’s most advanced AI processor, can be mass-produced on this 5-nanometer production line. This development has the potential to narrow the technology gap between China’s homegrown AI chips and Nvidia’s most popular graphics chips.

Production Challenges Remain

One of the most important challenges that SMIC faces, however, is whether it can produce complex chips on a large scale, or if the US will restrict its ability to do so. According to U.S. Commerce Secretary Gina Raimondo, China does not have the necessary capacity to mass-produce such components. The process of creating more advanced chips has resulted in additional costs for SMIC. The production costs for SMIC’s 5-nanometer and 7-nanometer chips are 40 to 50 percent higher than TSMC’s costs for chips of the same process. Additionally, SMIC’s yield rate for chips produced is only two-thirds of that of the same class of chips produced by TSMC.

Previous post

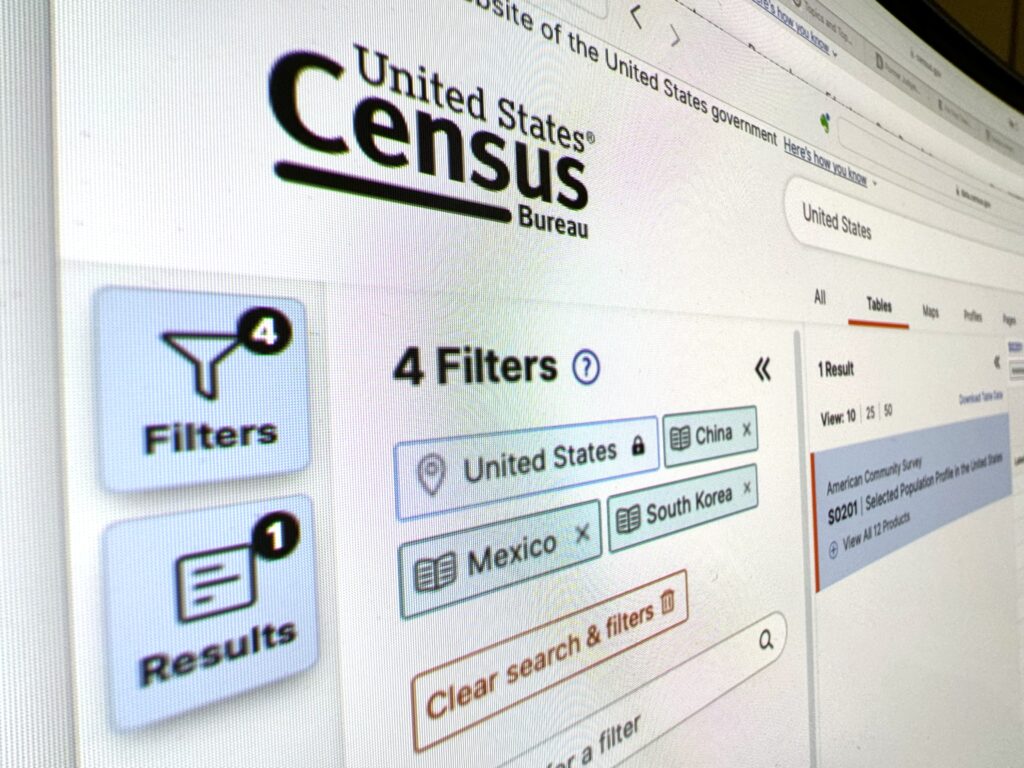

Mexico Surpasses China as Top US Trading Partner

Previous post

Mexico Surpasses China as Top US Trading Partner